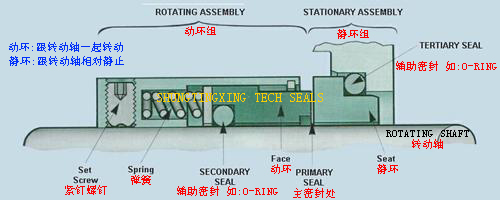

|

Sealing a rotating shaft on pumps, compressors,

mixing vessels and similar equipment, at its entry

to the casting, is most effectively achieved by

means of a

mechanical seal.

This device has two very flat radial surfaces, one

rotating with the shaft and the other connected to

the casing, axially pressed together by a spring and

hydraulic forces. The rubbing surfaces create the

'primary seal'. To allow for alignment tolerances,

shaft movement, and slight wear of the rubbing

surfaces, the component rotating with the shaft must

be not only flexibly connected to it, but also must

ensure no leakage of fluid at this joint. This

flexible connection is referred to as the 'secondary

seal'.

The component connected to the casing is normally

required to be replaceable, and the sealing element

used is called the 'tertiary seal'. |